Packaging Technology Progress

What is packaging

Let’s understand what packaging is before introduce packaging technology progress. Packaging is the continuation of the goods production process in the follow-up circulation process. It is an indispensable component of goods into the market and into thousands of households. Paper packaging refers to the production of cartons, paper bags and other packaging containers by printing and processing paper materials. The function of packaging is put forward in several aspects. 1. Protecting products. Protect the product from damage during handling or transportation, and to a certain extent from natural factors. Such as wind, sunshine, dust and so on. 2. Putting irregular shape products into regular shape packaging boxes can facilitate code storage and transport. 3. Printing the customer brand logo on packaging can highlight customer brand and play a role of invisible free advertising. 4. Through unique packaging design, attract clients’ attention, expand the influence of eyeball economy, promote clients to buy products and increase market share.

How do we know packaging technology goes rapidly

Paper packaging produce technology mainly covers printing, die-cutting, surface treatment, machine auto or manual assembling. With the rapid development of science and technology, packaging technology is also showing rapid development.

Printing technology improvement

First, look at the printing process, packaging paper can be offset printing, silk printing, UV printing, relief printing out rich and colorful customer design patterns. The most common paper packaging is offset printing. It took only 20 years for offset printing to develop from type printing and film printing to computer plate printing. At present, a few large printing enterprises have even begun to test run the electronic direct connection printing machine. It saves the printing cost and time greatly by save the print plate.

Die-cutting technology improvement

Die-cutting technology is also growing rapidly. Usually, workers make various shapes of cutter molds and put them into semi-auto beer machine by hand, inefficient and dangerous. Now widely used in various types of large-scale auto beer machine, high efficiency. It not only can beer common paper such as art paper, kraft paper and other thin paper, but also can beer all kinds of thick cardboard, corrugated paper. Even now there is a cylindrical auto beer machine controlled by computer. Its precision is like that of a printing press, and it’s working efficiency is dozens of times higher.

Surface handling technology improvement

Surface treatment technology also develops with the development of nowadays science and technology. With the rapid development of various high-precision intelligent foil machines, UV machines and lamination machines, more complex designs can be produced. Now there is a cold stamping process, its stamping effect process like printed, but more metal texture.

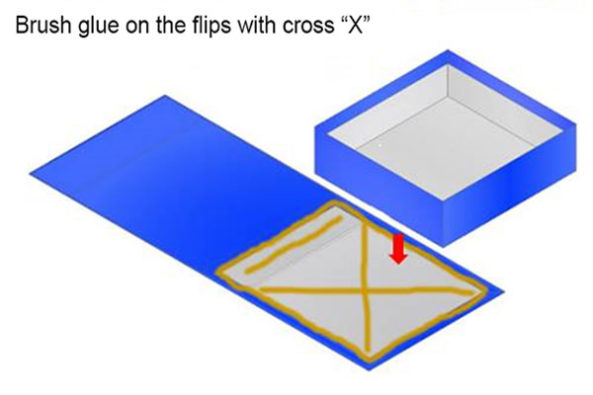

Paper packaging shaping technology improvement

Great progress has also been made in the final forming technology of gift boxes, cylinder boxes and paper bags. Comparing with the traditional manual box assembly, there are now fully auto production machines and even industrial robots that efficiently collaborate to produce gift boxes of various shapes. It’s not just a simple lid and base box, even drawer boxes, and magnet flip boxes can be manufactured automatically by machines.

Major Custom always keeps pace with the times, using new machines and learning new technologies. To achieve the goal of providing production efficiency, reducing costs and improve quality. The quality level of the factory has been far ahead in the same industry, but the price is 30% – 40% lower than the industry level. By updates, improve their own production level, to benefit customers. So that the company has achieved great development, in the leading position of the packaging and printing industry.