Surface treatment also called surface finish, surface handing, or Surface coating. High-end packaging often requires extensive surface treatment to modify. Proper surface treatment after printing can decorate the paper packaging box and improve the quality of the packaging. All paper packaging can be surface treated. Such as cylindrical paper boxes, square gift boxes, cardboard boxes, corrugated mailer boxes, magnet boxes, etc. It can do one or more surface treatment processes to enrich the design content and improve the appearance of the packaging.

Our surface treatment workshop can do a wealth of surface treatment processes, such as Spot UV, Hot foil stamping, Lamination, Embossing/Debossing, Gilltering, Graining. Below we will introduce these surface treatment processes to you one by one.

Spot UV

Definition: The special process of curing the ultraviolet photoresist on the surface of the printed product in full or partially.

Features: A variety of artistic special effects can be presented on the surface of the printed matter to make the printed matter more exquisite. UV can focus on decorating the logo, product graphics, slogan, etc. which customers need to express. UV is crystal-like crystal clear, shining, but also has a strong three-dimensional effect. The sense of fashion and individuality bursts out instantly to give you an unusual feeling.

Scope of application: cardboard paper tubes, packaging boxes, high-end packaging, paper shopping bag, etc.

Note: When do the UV process, it requires that printing is accurate, and the paper must not be too deformed.

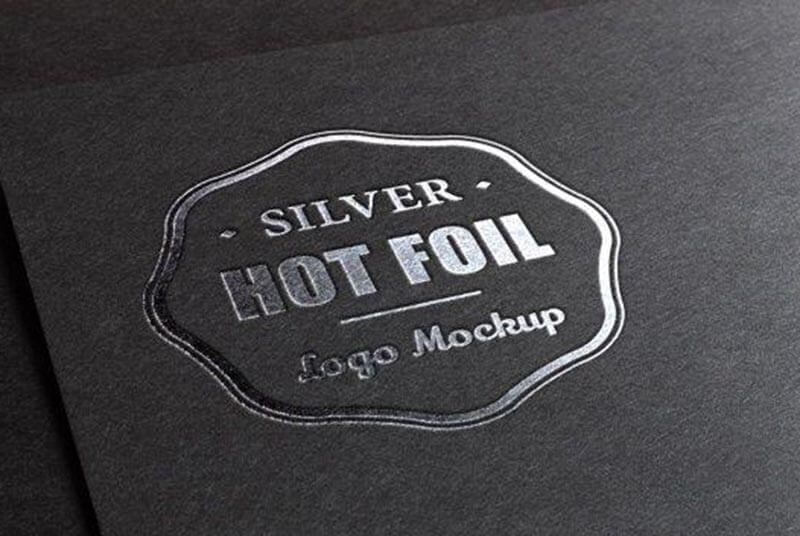

Hot foil stamping

Definition: A method of hot stamping metal foil onto printed paper with the help of certain pressure and temperature.

Classification: golden foil stamping, silver foil stamping, red color foil stamping, black color foil stamping, laser foil stamping .etc.

Special point: metallic luster, magnificent, make the printed picture have a strong contrast. It has the characteristics of clear patterns, a beautiful appearance, bright and eye-catching colors, and wear resistance. In packaging design, hot foil stamping can play a finishing touch and highlight the design theme.

Scope of application: suitable for very prominent text or logo. Mostly used in cosmetic packaging boxes, essential oil bottle cylinder boxes, eyeshadow palette, lipstick tubes, etc.

Note: It can be more remarkable when combined with the process embossing or embossing process.

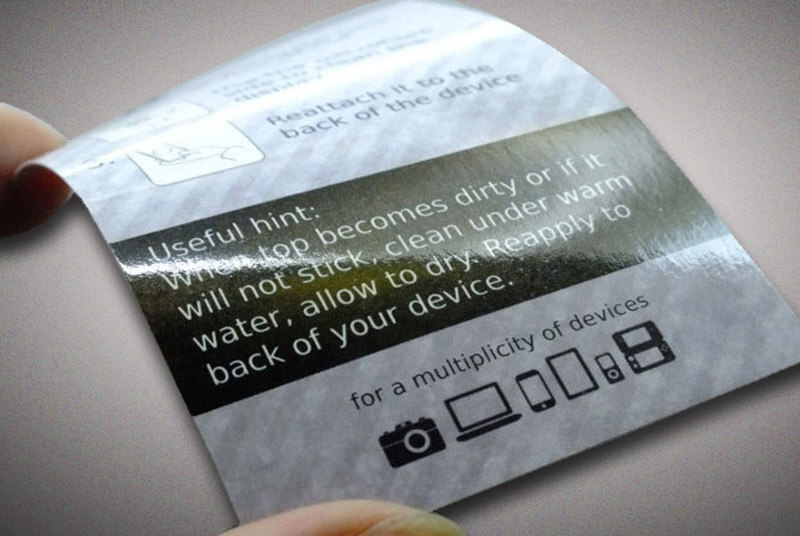

Laminating

Definition: The processing technology of covering the surface of the printed paper with a plastic film. It using an adhesive to bond them together after heating and pressing to form a printed case paper. Cover a thin polyethylene film on the surface of the printed paper.

Classification: Gloss lamination, Matt lamination, Soft-touch lamination

Features: The surface of the light-coated product is bright and luxurious. It is mostly used for case paper. The surface of the product packaging with the matte film is non-reflective and elegant. It is mostly used for image-based printing case paper. At the same time, it can enhance the strength of the packaging, improve the durability and waterproofness of the packaging.

Scope of application: Any gram of paper. But it will have bubbles when doing lamination on some grained fancy paper.

Note: paper with a thickness of 128 grams or less is a little easy to roll when doing lamination, workers should pay attention. The color saturation of the printed paper will slightly decrease after the matte film is coated. So printed image color will look a little darker after lamination coated.

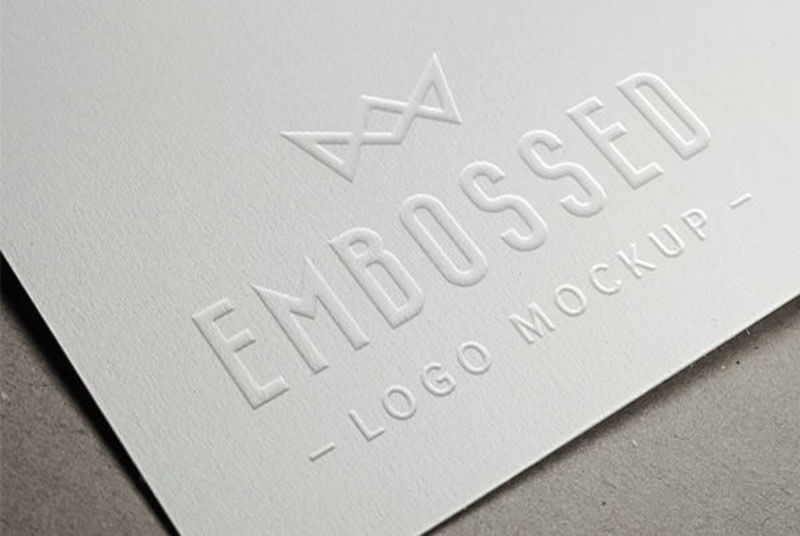

Emboss/Deboss:

Definition: Make embossing/deboss plates according to the customer’s design. Embossing/Debossing graphics and characters, showing patterns of different shades.

Classification: Emboss (outstanding), Deboss (deep sink).

Special point: After hitting the convex/concave, the graphics/text has an obvious sense of relief, which enhances the artistic appeal of the three-dimensional box. Bump embossing is a relief art of printing, which enhances brand expansion.

Scope of application: various brand cosmetic packaging, round tea cans, protein powder paper tube boxes, electronic cigarette packaging boxes, charger packaging boxes, etc.

Note: The thick cardboard of more than 200g has a significant effect on embossing/debossing. When applied to 128gsm, 157gsm face paper of rigid paper box, the effect is not as obvious as that on single-thick cardboard. Because the box has to be pressed and glued to thick cardboard. If you need to improve the effect, you need to make a thick embossed plate. But should pay attention don’t break the paper during the production process.

Gilltering:

Definition: Add colored shining powder to the ink containing photosensitizer, and then irradiate it with ultraviolet light to dry and cure it to the surface of the packaging box.

Classification: golden glitter, silver glitter, colorful glitter and so on.

Special point: The logo on the surface of the decorative packaging makes the graphics look more dazzling and colorful. It giving people a dazzling and dazzling feeling. Attract consumers’ attention and enhance brand attention.

Scope of application: various high-end cosmetic packaging boxes, eye shadow boxes, lipstick tubes, eyelash boxes, etc.

Note: The glittering surface treatment process requires a screen mold. Workers make this screen mold according to the glitter area of the customer’s design file. During the production process, workers need to evenly distribute the glitter material on the entire screen mold to ensure that there is glitter powder in all positions where glitter powder is needed.

Graining

Definition: using mechanical embossing or crumpled paper to form uneven patterns on the surface of paper or cardboard.

Sub-category: various patterns graining.

Features: Embossed paper improves its decorative effect through embossing. It makes the paper more textured and improves the level of packaging.

Scope of application: suitable for all kinds of art paper, kraft paper, black paper card.

Note: Many fancy papers with textures have already undergone Graining surface treatment. There are various textures of fancy paper for selection in our fancy paper catalog. Customers can preferentially choose fancy papers with specific textures. The price of grained fancy paper is cheaper than doing extra embossing/debossing processes.