What is the best packaging material?

Almost all products in our lives require a box or bag to protect the package. Packaging can not only protect products, but also increase product added value and promote product branding. Ordinary product packaging is divided by packaging material, mainly paper packaging, glass packaging, plastic packaging, PET / PVC film packaging, iron can / aluminum can packaging. These different packaging material have their own characteristics, and it is difficult to clearly state which packaging material is the best. However, in some respects, paper packaging material have obvious advantages and are worthy of promotion by government enterprises and institutions.

First of all, paper packaging material are the most environmentally friendly.

We all know that paper packaging materials are environmentally friendly materials that are easily degradable and environmentally friendly. But how much environmental protection is there? By comparing the natural degradation time of various materials we know:

Paper packaging materials: Degradation time is about 1-4 months. This means that the used carton, paper tube or paper bag is discarded and buried in the soil. It will naturally degrade into inorganic fertilizer in about three to four months. Generally, the carton or paper bag can be used several times. After the consumer finishes using the product, he can use the empty box to install other daily necessities for a period of time. After the final abandonment into paper packaging garbage, it is piled up in the garbage dump. It will be degraded in one to four months, which has little impact on the natural environment.

Tin cans of aluminum cans: Completely rusted back to nature for about 10 years. This means that after you have finished using the tin can/iron lid box, even if it is just a thin layer of iron, it will take another ten years for it to die. A tin can is placed in front of your eyes, you may feel that the impact is not great. But all the iron cans in the whole society are discarded into garbage. Each of which will disappear in ten years. Eventually there will be piles of discarded iron pipe waste. Although some institutions in the society recycle, most of them are discarded into garbage.

Aluminum paper cans: 50 years of existence. Since the aluminum surface can produce an anti-corrosion film by itself, it is less likely to die out than the iron can. Discards do not degrade in nature for a long time, they are also dangerous for animals. Small animals are easily cut or stabbed by such long-standing sharp cans.

Plastic packaging materials: natural degradation time of 100-500 years. We all know that plastics are made from petrochemicals. Some of these chemicals may never be biodegraded and remain in the soil. Even a small plastic bottle can take five hundred years to degrade. Plastic packaging materials have been used in large quantities because of their low price. Now become the main solid waste, known as white garbage. Not only is it abundant in the soil, but even the creatures in the ocean are deeply poisoned by plastic waste.

Glass jars: 1-2 million years. Glass is mainly composed of silicon, which is one of the most stable and durable minerals on the planet. When the glass bottle is used up, it will almost always exist in nature. Although glass does not release toxic and harmful substances into the soil or water, it is easily broken. When a large number of discarded glass fragments in nature, animals eat food or have food residue, they will suffer serious damage. Broken on the ground, it is also easy to cut the animal’s feet.

Therefore, from the above point of view, the paper packaging material is superior to other packaging materials in terms of environmental protection. Paper material made packaging can be naturally decomposed by natural microorganisms, and other materials are hardly degraded. Paper packaging is the most natural and environmentally friendly and easily degradable material.

Moreover, paper packaging material has excellent packaging technical characteristics.

Paper material itself has small stretchability, is not easily chemically reacted by heat and light, has good stability, and does not affect the products inside. This is suitable for food packaging, such as a large number of food packaging tubes, food packaging paper bags, milk boxes, etc. in daily life. The paper’s opacity provides covert isolation, making certain products unobservable from the outside of the package and meeting the packaging needs of some products.

Paperboard packaging material is easy to process and form, and can be cut by mechanical cutting to facilitate mass production. Due to the slight electrostatic properties of the paper, it is suitable for packaging flour products and high-speed online packaging. Paper packaging materials also have good breathability, softness, strength and controlled tear properties. The paper has good elasticity and toughness and can provide good protection for the packaged object. The paper is also characterized by lightweight and variety.

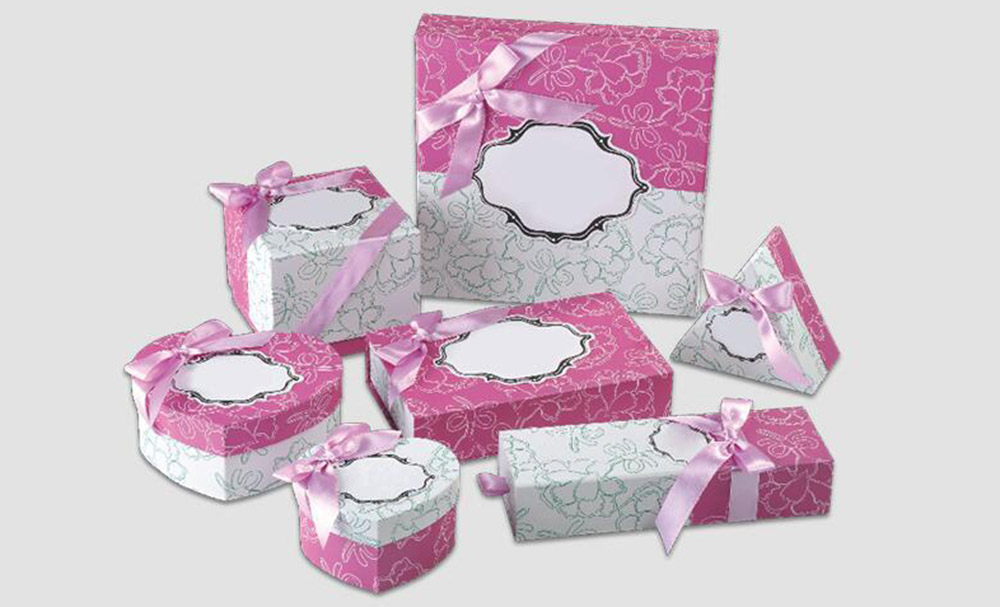

The paper packaging material has excellent composite properties and can be processed into a wide variety of packaging materials, such as thin paper and cardboard core suitable for gift boxes, paper tubes suitable for cylinder boxes, thick cardboard suitable for paper bags, suitable for carton Corrugated pit cardboard and so on. Nowadays, the technology of paper color box packaging has reached: moisture proof, waterproof, package curing, mildew proof, aseptic, package cutting, vacuum, body, anti-static, anti-odor, shrink, stretch, preservation, printing, labeling , wrap and so on. Moreover, the environmentally friendly color box materials have good flexibility, tearability, hardness controllability, and are easy to manufacture into various shapes.

Therefore, the paper environmental protection color box is now almost able to replace most of the other materials in the box. Paper packaging materials have good printing adaptability, easy to absorb ink, printing decoration and bonding processing, and can adapt to various printing. It can conveniently and cost-effectively customize the customized packaging design of customers to meet the individual packaging needs of customers.

Finally, the small-volume custom production of paper packaging materials has the advantage of being cheap.

Made of natural materials such as paper and wood, and discarded paper packaging materials can be recycled and reused. It can saving energy and environmental protection. The cost of raw materials for paper packaging materials is relatively low. The paper packaging material is light in weight, convenient for transfer and transportation. And the transportation cost is relatively low. The production of gift cartons is made from paper packaging materials. The order quantity of paper bags is lower than other materials. Customized paper packaging boxes are not like iron cans or plastic cans which need to make expensive molds first. The cost of customizing small packaging in small batches is low. It is easy to send low-cost finished products to customers. Compared with other custom metal packaging boxes, glass bottles and plastic boxes, it is easier for customers to customize different types of small-volume paper packaging boxes and paper bags.

With the continuous application of advanced equipment, the production of mechanical automation is becoming more and more popular. The cost of mass production of paper packaging boxes and packaging paper bags is getting lower and lower. The cost of high-volume paper packaging boxes and paper bags is getting closer to cheap plastics. But the natural safety and the environmental protection feature of the paper package is that the plastic package can’t catch up anyway.