Before paper box packaging design or mass production, it is an important content to make paper box sample by hand. The production of paper manual samples can help packaging designers and packaging engineers to find out the details that are difficult to detect in packaging design and drawing. And check whether the functions in the structural design of paperboard box are complete and applicable. When making packing box samples by hand, it needs to prepare the main tools. Including art knife, scissors, triangle plate, ruler (or parallel ruler, t-ruler, etc.), curve plate, cutting plate, etc.; and consumables such as double-sided adhesive tape, solid adhesive tape, paper material, etc.

The art knife and scissors use for cutting should be sharp and clean. The use of the knife should be mainly art knife, supplemented by scissors. In the packaging practice project, the paper materials used for the manual samples should be the same as the mass-produced paper boxes. In packaging order, generally, it should use the same paper material as the mass order will use which client want. Packaging engineers must inform client if using other paper material to make the sample box. No matter choose what kind of paper to make packing samples, the appearance of the package box shall be clean and beautiful.

Preparation for manual production of paper box packaging samples.

When making manual paper box sample, it needs a flat and large desktop as the workbench. Before making, the desktop and ruler must be cleaned and kept clean. After making the paper box sample, the tools and materials should be cleaned up in time. Workers should clean the garbage on the desktop should. And restore the workbench, ground and ruler tools clean and tidy. It can ensure that the surface of the work object is clean and tidy and easy to enter the state in the next operation. This is a good habit and professional quality that a packaging proof maker should have.

It recommends using more white cardboard when learning the structural design drawing of the paper box for the first time. So that the lines drawn on the paper show clearly and all parts of the paper box structure looks obvious. It usually draw the line on the back of the paper. It can select different thicknesses of paper flexibly according to the size of the box and the weight of the content. In addition to white cardboard, color cardboard, black and white gray cardboard, kraft paper, thick cardboard with texture effect can also be used for manual paper packaging box. Properly matching the paper color and paper grain can give the paper box a very beautiful display effect.

Tool consumables and its application in hand made of paper box sample

(1) pencil.

Cartridge packaging structure drawing can use ordinary pencils and mechanical pencils. The refill should use HB, B, 2B and other soft and hard models. In general, we recommend using automatic pencils to draw lines. It is more convenient to write down, the lines are thin and the depth of the marks is just right. Even if you make mistakes, it is easy to modify and erase. If you use ordinary pencils, you should sharpen the lead slightly before drawing. Make sure drawing the lines on the paper thinly. At the same time, the pen should be lighter when drawing. So that the lines are neat and accurate and easy to modify.

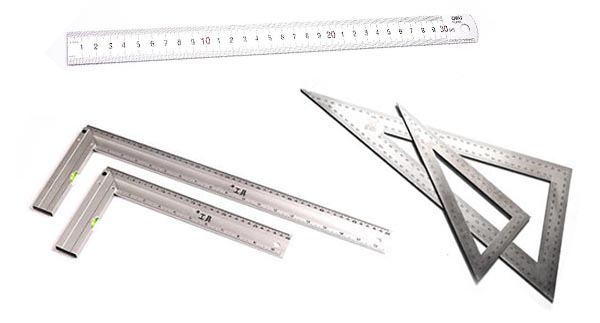

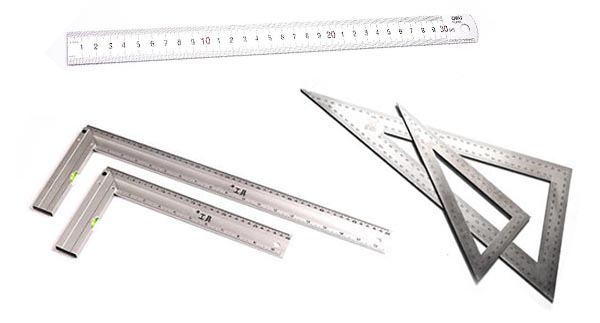

(2) Triangle plate, ruler, t-ruler and parallel ruler.

When drawing, it should use one or more of the above rulers in order to draw accurate vertical, horizontal and parallel lines. When the above tools are not complete, at least two triangle plates or a triangle plate plus a ruler T-square should be used. And when selecting a triangle plate, it needs to use a triangle plate dedicated to drawing, preferably with a protractor and a curve plate. Using ruler-type tools to accurately draw perpendicularly intersecting lines and parallel lines. During the operation, the above two lines must be accurately drawn. Otherwise, the box sample will be skewed and become a waste product.

In addition, pencils, especially ordinary pencils, will stain ink on the ruler when drawing lines along the ruler. The ink stain on the ruler will increase after drawing multiple times. It is easy to stain the paper surface. Therefore, after drawing for a period of time, you should use dry or a slightly moistening paper towel or cloth to wipe the ruler. Ensure that it can draw the next lines clean and tidy.

(3) Compass, curved plate.

When drawing the gift box packaging tongue, dust wing, bottom structure and other parts, it needs to modify the sharp outer corners arc-shaped to facilitate use and maintain beauty. At this time, it requires a compass to express it, and there are some irregular curve segments. Use curve plates to assist in drawing.

(4) Art knife, scissors.

A utility knife can be used to sharpen pencils. The cutting line of the carton needs to be cut with a utility knife. The blade of the utility knife is easy to be blunt. So you should often shorten or replace the blade to keep it sharp at any time to ensure that the cut lines are clean Smooth. When dealing with polylines, use a utility knife back on the reverse side of the paper. And swipe it with a medium intensity to show a very stiff line on the front side. For rounded arcs or other irregular curves, you can use scissors to trim. The cutter used in making the box should be a utility knife and scissors as a supplement.

(5) Eraser, double-sided tape, solid adhesive.

Eraser is used to erase the wrong lines or temporary auxiliary lines. It can also erase the stains left on the front of the paper box after the completion of the draft. It uses double-sided tape and solid adhesive to paste the paper box’s adhesive flap. Generally, the effect of double side tape is better than that of solid adhesive.

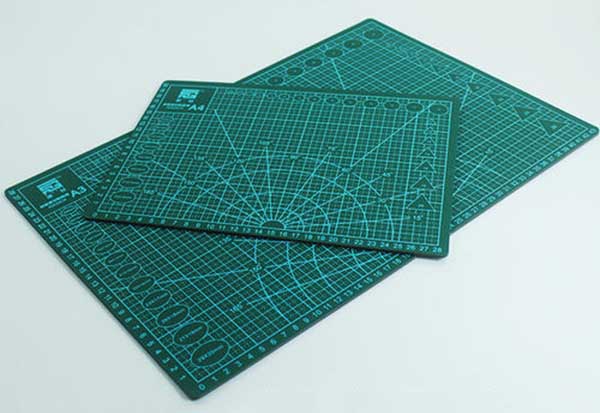

(6) Cutting board plate or cutting pad.

The cutting board plate is an important tool in the design and manufacture of cartons. It can protect the tabletop from being scratched by the art knife. At the same time, the scale bar on the board surface is convenient to measure the local size of cartons at any time when drawing and cutting packaging boxes.

(7) Different types of paper materials.

As mentioned above, in general, the packaging box samples of ordinary small commodities can be made of various colors of glossy cardboard. The box samples of local specialties and traditional foods can be made of kraft paper and various colors of cardboard with texture. While a few packaging design samples that need to be made of buffer. Such as protection porcelain, eggs, light bulbs and other commodities packaging can be made of corrugated paper. Choosing the right color and surface effect paper to make the sample of commodity packaging with specific theme is the experience that the students and practitioners who study packaging should accumulate.